Bagasse is produced from sugar cane after it is processed for making sugar. Nowadays, it is used to make various bagasse products and especially as material for environment-friendly food packaging and utensils, breaking away from the fate of most bagasse being disposed of in landfills or incinerators in the past. This article will describe how to use bagasse and the advantages of its use as a material.

What is Bagasse?

Bagasse can be used as a substitute for plastic, following are the properties of bagasse:

- plant-based

- renewable

- compostable

- environment-friendly material originating from sugar cane, one of the crops with the richest production in the world.

Bagasse is a by-product left over from sugar refining with sugar cane as the material. It can be used for many purposes, including straws, cups, dining utensils, cup lids, trays and bags.

What is Bagasse Used for Originally?

In the past, bagasse was usually used as boiler fuel in the sugar making process. It provided heat energy needed for refining sugar and generated partial electricity for the sugar refinery through steam power generation units. This approach is called cogeneration, which has the shortcoming of emitting carbon dioxide into the atmosphere.

In addition to boiler fuel, some bagasse is used for composting. It is collected and transported to a composting site and stirred periodically using excavators or other heavy machines so that the bagasse compost can be exposed to air adequately. The compost cannot be used until it has become thoroughly decomposed after a period of 10-12 months. If the bagasse compost is used directly on farmland without first undergoing maturation, it will absorb nitrogenous substances in the soil during maturation and affect the normal growth of the plants.

Since the annual output of sugar cane is amazing, boilers and compost cannot use all bagasse, so much of it rots naturally or is incinerated directly. As this pollutes the environment, many new applications are being developed, including replacing plastic raw materials, processing to solid recovered fuel (SRF), refining bioethanol, and mushroom grow bags, in the hope to utilize these bagasse resources appropriately.

What are Bagasse Products?

Bagasse Cutlery

Bagasse can be used to make knives, forks and spoons. Bagasse utensils are resistant to water, oil and high temperature and are suitable for pasta, cake, bread and soup.

Bagasse Straws

The use of bagasse straws is similar to commonly used plastic straws. The only difference is that bagasse straws contain plant fibers and pellets and have the color of sugar cane. Bagasse straws do not become soft when soaked in water and are resistant to high temperature. They can be soaked in tea, coffee, soda and other beverages without dissolving into poisonous chemicals or generating odors that affect the taste of the beverage.

Bagasse Bowl & Plate

Chemical coatings are usually applied to bowl and plate for oil resistance. However, bagasse dishes are characterized by oil resistance and can be used for salad, roasted meat, potato chips, popcorn, bread and other foods. They can be washed and used repeatedly without having to apply additional chemical coatings.

Bagasse Reusable Cup

Bagasse cups are mainly used as a substitute for paper cups and can be used for coffee or tea. The cups will start breaking down naturally after they have been used for a period of time. New cups can be used as a replacement and the old ones can be buried in the soil. They will decompose naturally and facilitate the carbon storage in the soil.

Bagasse Bag

Bagasse bags can be used as trash bags, shopping bags, food bags and for other applications. The light and thin material quality facilitates rapid decomposition of the bags in the composting environment. With plant fibers as the raw material, there are no concerns about pollution that plastic pellets cause.

How is Bagasse Product Produced?

Bagasse is collected and air-dried to remove moisture. Then, the dried bagasse is ground to make a granular material similar in nature to plastic pellets. These bagasse pellets can be used by machines that are usually operated for the production of plastic. A series of bagasse products is then manufactured through regular plastic production processes such as injection molding, extrusion and blow molding.

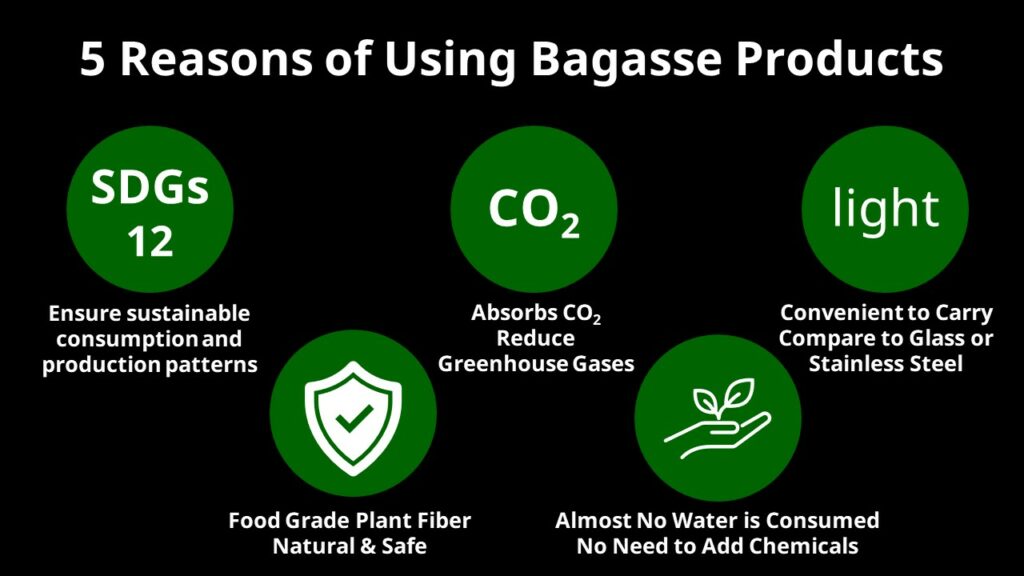

Why do We Start to Use Bagasse Products? 5 Benefits of Using Bagasse Products

Climate Change Mitigation

Bagasse originates from sugar cane. Sugar cane is a C4 carbon fixation plant that has a special photosynthesis mechanism that can increase the CO2 utilization efficiency and reduce the water consumption in the process. In comparison with C3 carbon fixation plants such as wheat, rice and soybean, sugar cane is adapted to arid land regions and absorbs a great quantity of CO2 in its growth process. If it can be processed into bagasse products, CO2 will ultimately be transformed to organic carbon through composting and stored in the soil.

Commitment to SDG12: Ensure sustainable consumption and production patterns

The United Nations proposed the “Sustainable Development Goals (SDGs)” in 2015. SDG 12 is “promoting green economies and ensuring sustainable consumption and production patterns.” Bagasse products can help achieve the sustainable management of natural resources by recycling waste and composting used products to substantially mitigate the generation of waste. At the same time, as daily necessities, bagasse products can improve consumers’ awareness of green consumption. Sugar cane is mainly grown in tropic developing countries, and the reuse of bagasse amounts to adding value to local agriculture.

Light & Convenient to Carry

The alternatives of many plastic food packaging materials are glass, wood or stainless steel. These materials have a specific density and weight and can easily injure people if they are not stored properly. Bagasse products are very light and handy. They are convenient to carry, pliable yet tough and not broken easily.

Natural & Safe material

Bagasse is mainly the by-product left over from sugar refining with sugar cane as the material. As food processing plants have undergone strict food safety testing, the chemical, heavy metal and pesticide content of bagasse is much less than the standard values. As a material containing natural plant fibers, bagasse can be used to produce healthy and safe products.

Raw Material Acquisition More Eco-Friendly Compared to Paper

Paper is also commonly used as a substitute for plastic food packaging materials, including paper cups, paper trays and paper bags. The raw material of paper is wood and its production requires deforestation. The quantity of the wood that can be provided by artificial afforestation is much less than the quantity of the wood supply needed for making paper. In the case of recycling and reuse of paper, deinking, desizing and bleaching are required for the reproduction of paper which requires many chemicals and consumes a lot of water. Bagasse raw material is an agricultural by-product and the manufacturing process requires almost no water resources. There are no concerns about chemical pollution and the manufacturing method is more environment-friendly compared to paper raw material.

The Advantages of Bagasse Products: Low Carbon, Compostable and Biodegradable

Low Carbon

Bagasse products are made from plant-based raw material and thus the carbon emissions are nearly zero. The heating and transformation process takes place at temperatures of 160°C at most (200°C for plastic) and no heavy machines or chemical agents are needed. As a manufacturer aware of environmental protection, Renouvo uses circulation water cooling for manufacturing processes to further reduce the consumption of water resources, ensuring that the raw material and production of bagasse products generates low carbon emissions.

Compostable and Biodegradable

Bagasse products have good decomposability and can be decomposed by microorganisms at room temperatures of 20±5°C. The resulting substance can be used as outstanding carbon-rich composting material and provide nutrients to the earth.

5 Bagasse Products FAQs

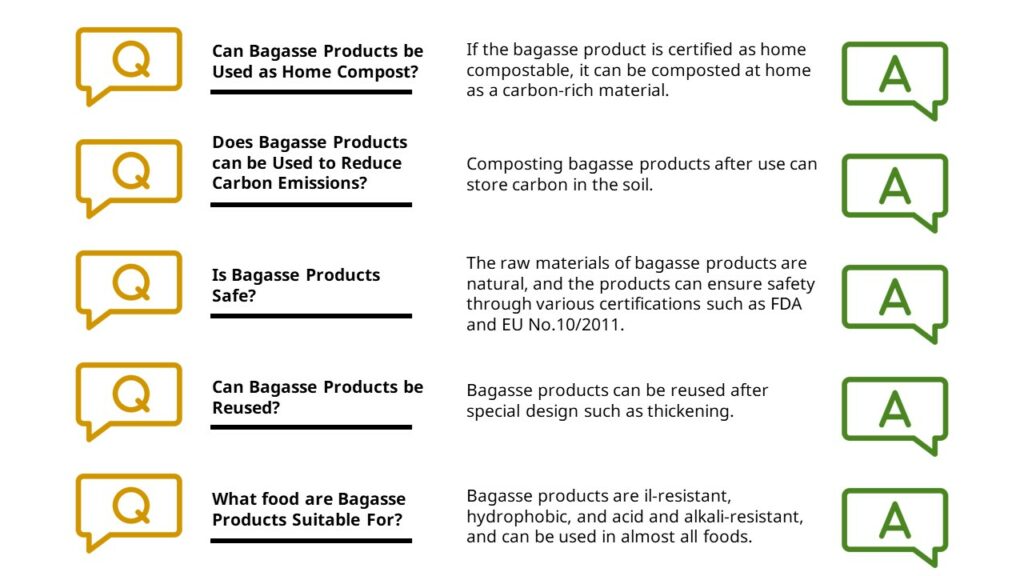

Can Bagasse Products be Used as Home Compost?

If PLA or other plastic or chemical substances are not added to bagasse, it can be used for home composting. However, it is advisable to confirm before purchase if the product concerned has a home composting certificate. The current internationally recognized home composting certifications mainly include DIN-Geprüft Home Compostable, ABA Home Compostable Verification Programme and TÜV OK compost HOME. They ensure that decomposition of bagasse products in a home composting environment has been proven in a laboratory.

Does Bagasse Products can be Used to Reduce Carbon Emissions?

Sugar cane transforms CO2 into organic carbon through photosynthesis during its growth. Composting used bagasse products can store carbon in the soil, which helps reduce CO2.

Is Bagasse Products Safe?

In addition to originating from natural raw material, bagasse products must undergo a series of safety-related certifications when they are used as food containers. For example, renouvo bagasse products have passed FDA certification (21CFR). SGS testing shows that the products do not contain the chemical substance PFAS and comply with EU No 10/2011 on plastic materials and articles intended to come into contact with food. Also, the products do not contain substances of very high concern (SVHCs). They comply with the regulations of local governments and are healthy and safe.

Can Bagasse Products be Reused?

Well-designed bagasse products can be used repeatedly. Though some products are designed as a substitute for disposable plastic products, such as straws, dining utensils, bags and dishes, there are manufactures, such as renouvo, increasing the thickness of the design of their bagasse products. This enables consumers to choose to use the products repeatedly, if appropriate, while dish washer testing can ensure that bagasse products can withstand being washed a certain number of times.

What food are Bagasse Products Suitable For?

In addition to drinks such as juice, soda, cocktails, coffee and tea, bagasse products are suitable for foods like roasted chicken, salad, pasta, potato chips and fries. They are oil-resistant, hydrophobic, and acid and alkali-resistant, and they can be used for almost all foods on the market.

What is the Future of Bagasse Products?

The mature applications of bagasse products are currently in the food packaging category. In fact, however, bagasse can be used as a substitute for plastics and can be uses for the cases of computers, communication devices and consumer products; building materials; and other commonly used plastics in everyday life such as credit cards, notebook cases, audio equipment cases, car bodies and floor materials. However, the fire-resistance of plant fibers remains a challenge to overcome. Manufacturers have started to develop cross-sector bagasse products and a greater penetration of bagasse products in everyday life is expected in the coming years, providing consumers with more opportunities to support green consumption.